Modern livestock farming demands reliable material handling solutions capable of withstanding intensive daily operations while maintaining peak performance. This comprehensive overview examines critical components, maintenance strategies, and technological innovations that position conveyor belts as indispensable assets in contemporary agricultural settings. From selecting durable materials to implementing AI-powered monitoring systems, these approaches minimize operational disruptions and maximize productivity.

The Critical Role of Livestock Conveyor Systems

Livestock conveyor systems serve as the backbone of efficient farm operations, significantly enhancing productivity and streamlining material transport. These systems comprise several essential elements working in harmony. The conveyor belt itself forms the primary carrying surface, facilitating the movement of feed, bedding, and waste materials. Supporting components including pulleys, rollers, and drive motors ensure proper tension, alignment, and power transmission throughout the system.

These systems excel at automating material flow, whether distributing feed to animals or removing manure from barns. By reducing manual labor requirements, they dramatically improve operational efficiency across livestock facilities.

Addressing Common Operational Challenges

Despite their advantages, conveyor systems face numerous challenges in agricultural environments. Exposure to moisture, temperature extremes, and abrasive materials accelerates wear and deterioration. Improper tensioning frequently leads to belt misalignment or slippage, compromising system efficiency. Overloading represents another prevalent issue, potentially causing belt damage or complete system failures that disrupt farm operations.

Optimizing System Longevity Through Proactive Maintenance

Implementing thorough inspection routines allows early detection of potential issues. Regular examinations should focus on identifying cracks, frayed edges, or unusual operational noises that may indicate developing problems. Prompt attention to these warning signs prevents minor issues from escalating into major repairs.

Maintaining cleanliness proves equally important, as accumulated debris negatively impacts both performance and hygiene standards. Selecting appropriate cleaning tools and solutions helps preserve belt integrity while removing contaminants.

Proper lubrication practices minimize friction between moving components, ensuring smooth operation and extending service life. Concurrently, regular alignment verification prevents uneven wear patterns that could shorten system lifespan.

Tension management remains a critical maintenance consideration. Maintaining optimal belt tension prevents slippage while avoiding excessive strain on drive components. Adhering to manufacturer specifications ensures consistent, efficient performance.

Selecting Appropriate Materials for Demanding Environments

Material selection significantly influences system performance under challenging operating conditions.

Heat-resistant compounds such as specialized rubber blends or engineered polymers demonstrate exceptional performance in high-temperature applications commonly found in processing facilities. These materials withstand thermal stress while maintaining structural integrity.

For systems exposed to moisture or corrosive substances, anti-corrosion treatments provide essential protection against rust and material degradation. These coatings dramatically improve durability in harsh agricultural environments.

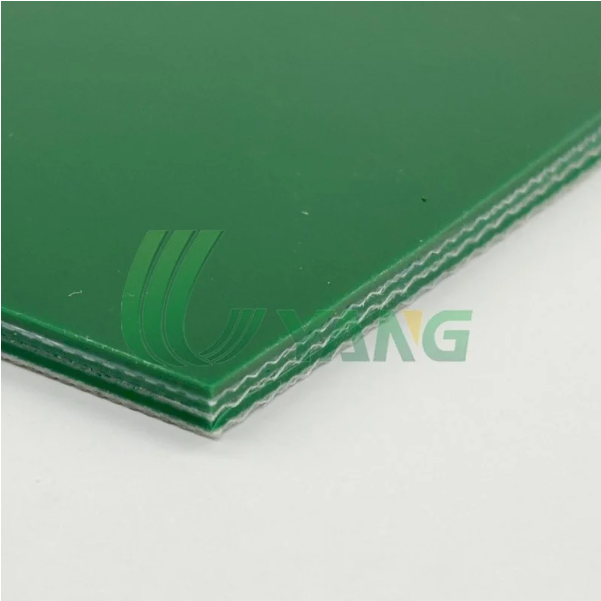

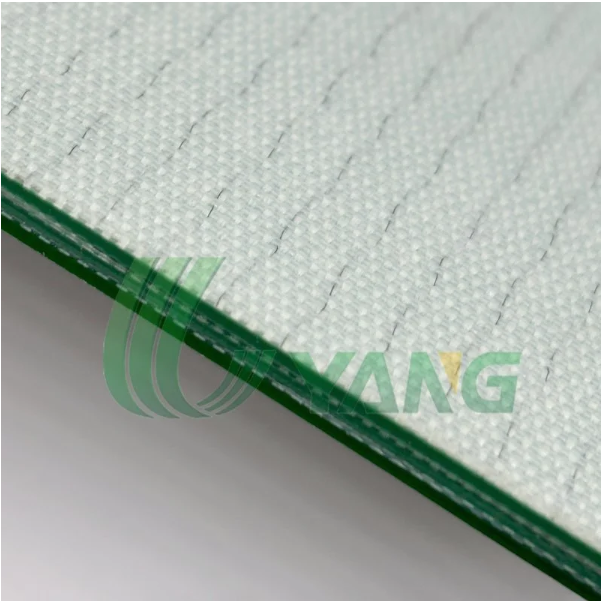

Industry leaders like Uyang Belting offer comprehensive product lines specifically engineered for livestock applications. With decades of experience, their solutions combine durability with operational efficiency tailored to agricultural requirements.

Operational Best Practices for Enhanced Efficiency

Effective load management represents a fundamental aspect of conveyor system optimization.

Preventing overloading situations protects both the belt and drive components from excessive stress. Strict adherence to manufacturer-rated capacity limits ensures safe, reliable operation.

Implementing proper loading techniques that distribute material evenly across the belt width prevents imbalance issues. This practice minimizes uneven wear while maintaining proper tracking and alignment.

Speed adjustment based on material characteristics further optimizes handling efficiency. Lower speeds prove ideal for delicate materials like feed pellets, while higher throughput rates better suit bulkier commodities.

Technological Advancements Transforming Conveyor Operations

The integration of automation technologies has elevated conveyor system capabilities to unprecedented levels. Smart monitoring solutions and AI-driven maintenance protocols establish new benchmarks for reliability in agricultural applications.

Intelligent Monitoring Solutions

Modern sensor networks provide real-time operational data, continuously monitoring critical parameters including belt tension, temperature, and wear patterns. This constant surveillance enables early fault detection, preventing minor issues from developing into major failures.

AI-powered analytical tools process sensor data to identify performance trends and predict component failures. This predictive capability facilitates proactive maintenance scheduling, dramatically reducing unplanned downtime while extending equipment service life. The resulting optimization delivers measurable improvements in both performance metrics and operational costs.

Innovative Solutions from Industry Leaders

Uyang Belting stands at the forefront of conveyor technology innovation. Their expansive 80,000-square-meter manufacturing facility houses fifteen automated production lines, delivering cutting-edge solutions specifically designed for livestock operations.

Selecting Optimal Equipment for Specific Requirements

Choosing appropriate belt specifications requires careful consideration of operational demands. Key selection factors include material composition, load capacity requirements, and environmental conditions. Heavy-duty applications typically benefit from rugged rubber constructions offering superior abrasion resistance, while lighter-duty feed handling operations may utilize efficient PVC alternatives.

Custom-engineered solutions provide significant advantages by precisely matching system capabilities to operational requirements. Whether handling feed distribution or waste removal, tailored designs from reputable manufacturers optimize both durability and performance.

The Importance of Operator Training and Maintenance Protocols

Comprehensive operator training programs ensure proper system utilization and maintenance. Personnel should master essential techniques including correct loading procedures and tension adjustment methods to prevent common issues like overloading or misalignment.

Establishing structured maintenance schedules guarantees long-term system reliability. Routine inspections facilitate early problem detection, while systematic cleaning prevents debris accumulation. Consistent lubrication routines minimize component wear, preserving optimal operating conditions throughout the equipment lifecycle.

By implementing these comprehensive strategies, livestock operations can maximize the value of their conveyor investments while maintaining efficient, trouble-free material handling capabilities.

SOURCE:https://www.uyangbelt.com/

0 comments

Be the first to comment!

This post is waiting for your feedback.

Share your thoughts and join the conversation.