LEDs (Light Emitting Diodes) have revolutionized the lighting industry with their energy efficiency and versatility. These semiconductor light sources emit light when voltage is applied, making them ideal for a wide range of applications. As an SEO specialist and copywriter, I understand the importance of creating unique and engaging content that resonates with our audience. In this article, we will explore the world of adhesives for LEDs and lighting, highlighting their applications and the different types of adhesives available.

What are LEDs?

What are LEDs?

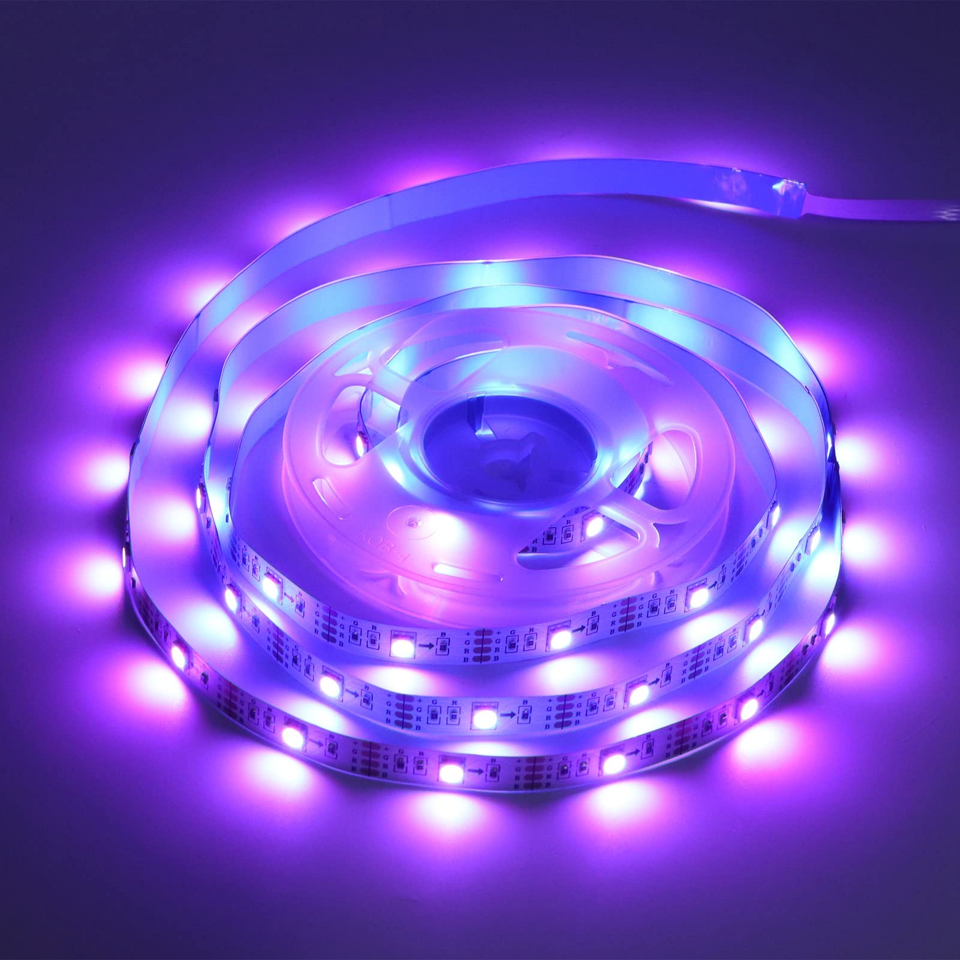

LEDs were originally developed as low-intensity infra-red light sources for devices like TV remotes. However, they have evolved to produce all colors of the visible light spectrum. The introduction of UV-emitting LEDs has been a game-changer for adhesive manufacturers, as they can now be used to cure UV adhesives. LEDs with multiple "legs" offer more color output from a single LED, with RGB LEDs allowing the generation of most colors. The energy efficiency and long lifespan of LEDs make them a popular choice for various lighting applications.

Read more: Can the LED Light be cut to fit a specific length?

What's new in the LED market?

The LED device market is constantly evolving, with advancements in energy efficiency and lighting output. LEDs have replaced traditional incandescent lighting in many applications, including desk lamps, room lighting, commercial lighting, outdoor lighting, and even vehicles and aerospace. LED streetlamps are gaining popularity due to their energy-saving capabilities and low maintenance requirements. The versatility of LEDs allows for innovative lighting designs, such as the Audi vehicle lamp clusters or the jaw-dropping effects seen in this year's Eurovision stage lighting.

Read more: Is the LED Light waterproof?

Applications for adhesives for LEDs and Lighting

Potting LEDs

LED lights are often potted into strips that are inserted into indoor and outdoor flooring joints. These strips add an attractive touch to public spaces and have become more common in car parks and parking lots. Clear adhesives with excellent optical properties are ideal for potting LEDs, as they allow as close to 100% light transmittance as possible. These adhesives should also have good resistance to wear and tear, weathering, water, and sunlight aging. For longer lighting strips, it is essential to consider using slightly more flexible adhesives to accommodate differential thermal expansion and contraction.

Read more: Review Abtong LED Light:

General Bonding

Adhesives play a crucial role in the lighting industry. They are used to bond electronic PCBs, lamp holders, and light reflectors. High-temperature adhesives are necessary for industrial lighting and stage/theatre lighting, as they can withstand temperature extremes. Adhesives are also used for wire tacking, bonding heat sinks to dissipate heat, and attaching components. The use of adhesives eliminates the need for bulky fasteners, providing a clean and aesthetically pleasing solution. Adhesives also provide a 100% seal against moisture and prevent rattling, making them ideal for automotive applications where vibration is a concern.

Sealing

Sealing is an essential application for adhesives in the lighting industry. Adhesives are used to create a seal between a lamp lens and the external housing, ensuring protection against environmental factors. For public areas and street lighting, sealants must be resistant to rain, hail, sunshine, and even vandal attacks. In such cases, the strength of the adhesive is prioritized over its aesthetic appeal to withstand potential vandalism and theft.

Types of Adhesives

There are various types of adhesives available for bonding, potting, and sealing LEDs and lighting components. Here are some commonly used adhesives in the industry:

Epoxy

Epoxy glue is commonly used for clear potting of LEDs. It consists of a two-part epoxy resin and hardener that cures at ambient temperatures. Choosing a low viscosity, slow-setting adhesive helps minimize the risk of air bubble entrapment. Other techniques, such as mixing under vacuum or using vibration tables, can further eliminate air bubbles.

MS Polymers

Flexible clear MS-polymers are excellent for creating a water-impervious seal between lamp parts. These adhesives do not require mixing and do not yellow in sunlight. They provide flexibility and are resistant to rain and hail, making them ideal for lengthy sections that require flexibility.

High-temperature cyanoacrylates

High-temperature cyanoacrylates are instant adhesives that are popular for reflector-type applications in lighting. They can withstand high heat and cure in seconds, making them suitable for high-speed production lines.

Threadlockers

Threadlockers are essential for securing bolts and preventing vibration loosening in lighting applications. For small bolts with fine threads, low viscosity anaerobic threadlockers are ideal. Medium-strength threadlockers are recommended if future maintenance and disassembly are anticipated.

Thermally conductive adhesives for heat dissipation

For applications that require heat dissipation and thermal management, thermally conductive adhesives are available. These adhesives are designed to bond heat sinks and other devices where good heat transfer is required. They come in different formulations, such as single-part heat cure epoxy, two-part epoxy, and two-part structural acrylics.

For further assistance regarding adhesives for LED and lighting applications, please feel free to contact Permabond. Our chemists will be happy to provide product recommendations and answer any questions you may have.

Frequently Asked Questions

Q: Can adhesives be used to bond LEDs in flooring joints?

A: Yes, adhesives are commonly used to bond LEDs in flooring joints. Clear adhesives with excellent optical properties and resistance to wear, tear, weathering, water, and sunlight aging are ideal for this application.

Q: Are there adhesives that can withstand high temperatures in lighting applications?

A: Yes, high-temperature adhesives, such as high-temperature cyanoacrylates, are suitable for lighting applications that involve high heat. These adhesives can withstand temperature extremes and cure quickly.

Q: What types of adhesives are recommended for sealing lamp components?

A: Clear, colorless, and non-yellowing sealants are commonly used for sealing lamp components. These sealants should be resistant to environmental factors such as rain, hail, sunlight, and vandalism.

Q: Can adhesives be used to bond heat sinks in lighting applications?

A: Yes, thermally conductive adhesives are specifically designed to bond heat sinks and other devices where good heat transfer is required. These adhesives come in different formulations to suit various substrates and application processes.

Q: Can threadlockers be used in lighting applications to prevent vibration loosening?

A: Yes, threadlockers are commonly used in lighting applications to secure bolts and prevent vibration loosening. Low viscosity anaerobic threadlockers are ideal for small bolts with fine threads.

Note: This article has been created based on the provided content, but has been rewritten to offer a unique and engaging reading experience.

Austin Delatorreさんをフォローして最新の投稿をチェックしよう!

0 件のコメント

この投稿にコメントしよう!

この投稿にはまだコメントがありません。

ぜひあなたの声を聞かせてください。